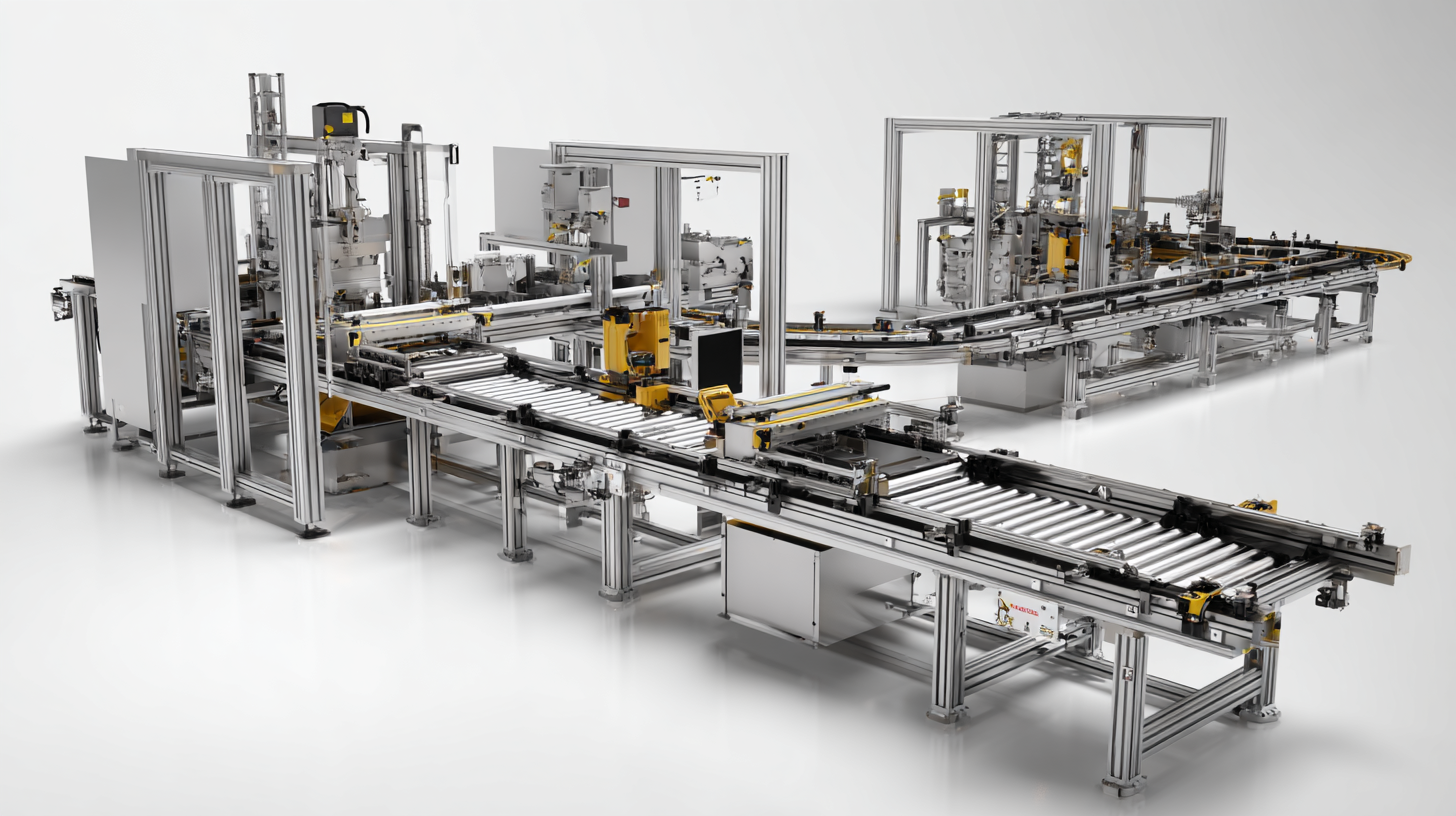

In today’s fast-paced manufacturing environment, the efficiency and effectiveness of production lines can significantly impact a factory’s overall productivity and profitability. One essential component of this efficiency is the implementation of robust Assembly Conveyor Systems. These systems streamline the movement of materials and components, enabling manufacturers to optimize workflows and reduce downtime. However, the successful integration of assembly conveyors requires careful consideration of various factors, including design, layout, and operational requirements. In this comprehensive guide, we will explore the numerous reasons why investing in effective assembly conveyor systems is crucial for modern factories. From enhancing throughput and minimizing labor costs to improving product quality and adaptability, understanding the key elements of these systems can empower manufacturers to make informed decisions that drive long-term success.

When choosing assembly conveyor systems for your factory, several key factors must be considered to ensure efficiency and productivity. The design of the conveyor should align with the specific layout and workflow of your facility. This entails evaluating the dimensions and capacity that suit your production needs, as well as considering how the conveyor will integrate with other equipment. For instance, a modular system can provide the flexibility necessary for quick adjustments as production demands evolve.

Another vital consideration is the type of materials being transported. Different products require different handling methods; therefore, the conveyor system must be tailored to accommodate the weight, size, and fragility of your items. Additionally, it's essential to think about maintenance needs and the overall durability of the system. Selecting high-quality components can lead to lower maintenance costs and reduced downtime, ultimately enhancing operational efficiency in your factory.

When it comes to optimizing manufacturing efficiency, selecting the right conveyor system is paramount. A recent report from the Material Handling Industry of America (MHIA) highlights that investing in conveyors can lead to a 30% increase in productivity. However, with various types of conveyors available—belt, roller, and overhead—factories must carefully evaluate their operational needs.

Belt conveyors, for instance, are ideal for transporting loose materials and are commonly used in assembly lines. They can handle both lightweight and heavy products, offering a smooth, continuous flow. In contrast, roller conveyors are best suited for heavier materials and are known for their durability, boasting a life cycle that can exceed 20 years under optimal conditions. According to data from the Conveyor Equipment Manufacturers Association (CEMA), roller conveyors can reduce labor costs by up to 40%, making them a favorable choice for many factories.

Overhead conveyors, on the other hand, provide unique advantages for production lines with height restrictions or for non-standardized products. Their design allows for efficient utilization of floor space and can significantly increase production flexibility. Studies show that overhead systems can improve space efficiency by up to 50%, allowing manufacturers to scale operations without the need for extensive facility modifications. Careful consideration of these conveyor types based on specific factory needs will ensure a more effective and efficient manufacturing process.

When considering assembly conveyor systems for your factory, one of the most critical decisions revolves around the choice between manual and automated options. Manual assembly conveyors require human intervention at each step, allowing for flexibility and adaptability in processes, especially in low-volume production settings. They often involve lower initial costs and can be tailored more easily to specific tasks. However, this approach can lead to inefficiencies, as the speed and reliability of human workers can vary greatly, potentially resulting in increased labor costs over time.

On the other hand, automated assembly conveyors offer significant long-term benefits, including increased speed, consistency, and reduced labor requirements. While the upfront investment can be substantial, automation can significantly decrease the total cost of ownership by minimizing errors and downtime. Automated systems are ideal for high-volume production where the ROI can be calculated based on the efficiency gains. Ultimately, a thorough cost-benefit evaluation is essential in determining which conveyor system best aligns with your factory’s production goals and budget constraints. By analyzing current workflows and production demands, you can make an informed decision that enhances operational efficiency and drives profitability.

In the pursuit of maximizing efficiency in assembly conveyor systems, performance metrics play a crucial role in evaluating various models. Recent advancements in technology have provided new insights into improving conveyor system performance, such as the optimization of switching sequences in AC-AC converters. This innovative approach not only enhances safety but also boosts overall system performance, highlighting the importance of integrating cutting-edge technology into existing conveyor designs.

Moreover, the development of intelligent predictive maintenance systems represents a significant leap in addressing operational challenges within industrial conveyor systems. By employing machine learning techniques, such as random forest algorithms, these systems can foresee potential failures and minimize downtime, thereby ensuring seamless production flow. Incorporating such smart solutions enables factories to not only monitor efficiency across different conveyor models but also make informed decisions that lead to substantial operational improvements. Emphasizing a combination of performance evaluations and predictive analytics will empower manufacturers to refine their conveyor systems and boost productivity significantly.

| Model Type | Max Load Capacity (kg) | Speed (m/s) | Power Consumption (kW) | Efficiency Rating (%) | Maintenance Frequency (months) |

|---|---|---|---|---|---|

| Belt Conveyor | 1000 | 1.5 | 1.5 | 85 | 6 |

| Roller Conveyor | 500 | 2.0 | 1.0 | 90 | 12 |

| Chain Conveyor | 2000 | 1.2 | 2.0 | 80 | 8 |

| Magnetic Conveyor | 750 | 1.0 | 1.2 | 88 | 10 |

| Flexible Conveyor | 300 | 1.8 | 0.8 | 75 | 5 |

The future of assembly conveyor systems is set to be revolutionized by innovative designs and cutting-edge technology. Recent industry reports highlight that automation is projected to increase productivity in manufacturing processes by up to 30% by 2025. This shift is being driven by advancements such as smart conveyor systems that utilize IoT technology to monitor performance and prevent downtime, enabling manufacturers to respond quickly to production demands.

Additionally, the integration of artificial intelligence (AI) in conveyor design is paving the way for enhanced operational efficiency. AI algorithms can optimize routing and sorting processes, reducing material handling times dramatically—by as much as 20%, according to a 2023 report by the International Automation Institute. Furthermore, the trend toward modular conveyor systems allows for greater flexibility in assembly line configurations, making it easier to adapt to changing production needs and facilitating a leaner manufacturing process. As these innovations continue to unfold, factories that embrace them will likely lead the charge in the next industrial revolution.