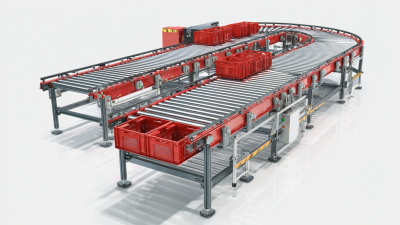

In today's fast-paced manufacturing and logistics environments, optimizing operational efficiency is more crucial than ever, especially when it comes to Conveyor Machines. According to a report by the Material Handling Industry of America, the adoption of advanced conveyor systems has been shown to enhance productivity by up to 30%, significantly reducing the time goods spend in transit and improving overall workflow. With the global conveyor system market expected to reach $9 billion by 2026, manufacturers are increasingly focusing on ways to upgrade these essential machines. Implementing strategic enhancements not only boosts throughput but also lowers operational costs, making a compelling case for ongoing investment in Conveyor Machine technology. This blog will delve into seven actionable tips designed to help you elevate your Conveyor Machine efficiency by an impressive 30 percent, ensuring that your operations remain competitive in an ever-evolving industrial landscape.

Regular maintenance of conveyor systems is crucial for ensuring optimal performance and efficiency in industrial operations. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), an estimated 70% of conveyor failures can be attributed to a lack of proper maintenance. Routine checks and servicing can not only extend the lifespan of the machinery but also prevent costly downtimes that can disrupt production schedules. Implementing a structured maintenance plan can lead to a performance improvement of up to 30%, as highlighted in various industry case studies.

Moreover, observing best practices in maintenance can significantly enhance safety and productivity. The National Safety Council states that improperly maintained equipment is a leading cause of workplace accidents. By prioritizing regular inspections, lubrication schedules, and timely component replacements, facilities can ensure that their conveyor systems operate smoothly and safely. The long-term benefits of maintenance extend beyond immediate cost savings; they can also improve the overall efficiency of operations, leading to sustainable growth in productivity and profitability.

Implementing smart technology solutions is crucial in enhancing conveyor machine efficiency. By utilizing advanced monitoring systems, businesses can gain real-time insights into conveyor performance. This technology leverages sensors and IoT devices to track critical metrics such as speed, load, and downtime. With this data, operators can identify bottlenecks or inefficiencies and take immediate corrective actions, thus streamlining operations and increasing overall output.

Furthermore, predictive maintenance technologies enable companies to foresee potential equipment failures before they occur. By analyzing data patterns, businesses can schedule maintenance during non-peak hours, minimizing disruptions and prolonging the lifespan of their conveyors. This proactive approach not only saves on repair costs but also boosts the reliability of the operations. Overall, integrating smart technology into conveyor systems is a strategic investment that can significantly enhance productivity and efficiency.

| Tip | Description | Expected Efficiency Improvement (%) |

|---|---|---|

| Implement IoT Sensors | Integrate sensors to monitor the performance and condition of your conveyor systems in real-time. | 5% |

| Use Predictive Maintenance | Adopt predictive maintenance strategies to reduce downtime and repair costs. | 10% |

| Optimize Layout Design | Revise conveyor layout to eliminate unnecessary turns and improve material flow. | 8% |

| Regular Training for Operators | Provide continuous training to operators to enhance their operation skills. | 3% |

| Energy Management Solutions | Implement energy-saving technologies to reduce power consumption. | 4% |

| Data Analytics | Utilize data analytics to identify trends and streamline processes. | 6% |

| Upgrading Conveyor Equipment | Consider upgrading to modern, more efficient conveyor technologies. | 15% |

Training employees on best practices for operating conveyor systems is key to enhancing efficiency and productivity. When workers are well-informed about the operational aspects of conveyor machines, they can significantly reduce downtime caused by mishandling or improper use. Regular training sessions should cover the various functionalities of the conveyor system, maintenance practices, and troubleshooting techniques, ensuring that employees are equipped to handle any challenges that arise during operation.

Moreover, fostering a culture of safety and awareness around conveyor use is essential. Employees should understand the importance of following standard operating procedures, which minimizes the risk of accidents and injuries. Implementing hands-on training that includes simulations can help workers become familiar with the equipment in a controlled environment, allowing them to build confidence before they engage with the machinery on the production floor. Encouraging open communication about best practices among team members further enhances operational efficiency and ensures that everyone is aligned in their understanding of effective conveyor machine use.

Analyzing and adapting conveyor layouts is crucial for maximizing workflow efficiency in any production environment. An effective conveyor system is not a one-size-fits-all solution; it must evolve alongside the evolving demands of your operations. Regular assessments of your conveyor layout can identify bottlenecks and inefficiencies that may be hindering overall productivity. Techniques such as simulation modeling and flow analysis can provide valuable insights into how materials and products move through your facility, enabling you to make informed adjustments.

Moreover, involving team members in the layout evaluation process can yield fresh perspectives and innovative ideas. Encourage feedback from operators and logistics staff, as they work closely with the systems daily and can pinpoint issues that might otherwise go unnoticed. By combining their insights with data-driven analysis, businesses can implement practical layout changes that enhance both speed and efficiency. Ultimately, a proactive approach to regularly reviewing and refining the conveyor system layout can lead to significant improvements in operation, contributing to an impressive increase in overall productivity.

This chart illustrates the potential improvements in efficiency (%) when optimizing conveyor layouts through regular analysis and adaptation. The values represent various scenarios of workflow adjustments over a year.

Investing in high-quality components is essential for enhancing the durability and efficiency of conveyor systems. According to a report from the Conveyor Equipment Manufacturers Association (CEMA), conveyor downtime can account for up to 20% of operational costs in the manufacturing industry. By selecting premium materials and components, companies can significantly reduce maintenance frequency and extend the lifespan of their equipment. For instance, using high-grade bearings and drive systems can diminish wear and tear, leading to a potential increase in operational reliability by 30%.

Moreover, research indicates that upgrading to enhanced conveyor systems can improve energy efficiency by as much as 25%. This is particularly relevant as energy costs continue to rise, and businesses seek ways to reduce their overhead costs. For example, investing in energy-efficient motors or drive systems not only contributes to a lower carbon footprint but also realizes substantial savings on energy bills. Combining these quality components with regular performance assessments ensures that conveyor systems operate at peak efficiency, ultimately leading to improved productivity and slower depreciation rates.