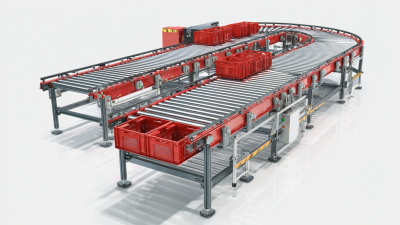

In today's fast-paced manufacturing landscape, optimizing the Heavy Roller Conveyor Assembly Line is pivotal for enhancing operational efficiency and productivity. According to a recent report by the International Association for Production Engineering, companies that implement optimized conveyor systems can see efficiency improvements of up to 30%. Moreover, the ability to seamlessly integrate automation technologies into the conveyor assembly line can result in significant reductions in labor costs and production timelines. As industries increasingly turn to advanced manufacturing solutions, it has become imperative for businesses to leverage the potential of Heavy Roller Conveyor Systems, ensuring minimal downtime and maximum throughput. This article aims to explore effective strategies that can be employed to fine-tune these assembly lines, ultimately driving greater performance and competitiveness in the market.

When optimizing a heavy roller conveyor assembly line, identifying key performance indicators (KPIs) is crucial to ensure maximum efficiency. These KPIs provide measurable values that reflect the effectiveness of the conveyor system in meeting production goals.

Common KPIs to consider include throughput rate, downtime, and operational speed. Throughput rate measures the number of goods processed in a given time, helping to identify bottlenecks. Downtime, whether planned or unplanned, significantly impacts productivity and should be minimized. Operational speed indicates how swiftly the conveyor system moves materials, which directly affects efficiency levels.

In addition to the basic KPIs, organizations should also assess energy consumption and maintenance frequency. Monitoring energy usage helps in evaluating the cost-effectiveness of the conveyor system, while a high maintenance frequency may signal the need for equipment upgrades or process redesigns to enhance reliability. By regularly analyzing these metrics, companies can make data-driven decisions to streamline their operations, reduce waste, and improve overall performance in their heavy roller conveyor assembly lines.

Optimizing a heavy roller conveyor assembly line requires a meticulous approach to load capacity, particularly in balancing weight distribution to prevent overstrain. When assembly lines operate under excessive weight load, not only is there a risk of mechanical failure, but it can also lead to inefficiencies and increased downtime. One effective method to address this is by conducting a thorough analysis of the conveyor's load-bearing capacity and ensuring that the distribution of weight is evenly managed across all rollers. Implementing this strategy can reduce stress on each component and enhance the overall durability of the system.

In addition, regular maintenance checks should be conducted to monitor the condition of the rollers and the assembly line structure. By proactively identifying areas that may be prone to overstrain, businesses can make necessary adjustments to load allocation before issues arise. Utilizing advanced monitoring technologies, such as sensors and data analytics, can further aid in evaluating load distribution in real-time, allowing for quick adjustments that keep the assembly line operating smoothly and efficiently. This proactive and analytical approach contributes significantly to maintaining high operational standards and maximizing the efficiency of heavy roller conveyor systems.

Incorporating advanced control systems into heavy roller conveyor assembly lines facilitates real-time monitoring and adjustments, significantly enhancing operational efficiency. A recent report by the Material Handling Industry of America (MHIA) indicates that the implementation of smart manufacturing technologies can yield efficiency improvements of up to 30%. These systems enable operators to track key performance indicators (KPIs) such as throughput, equipment status, and energy consumption in real time, allowing for data-driven decision-making and swift responses to any discrepancies.

Moreover, the integration of IoT (Internet of Things) technologies allows for predictive maintenance, which can minimize downtime by 20-50%, according to research from McKinsey & Company. By utilizing sensors and connected devices, businesses can foresee equipment failures and schedule maintenance before disruptions occur. This proactive approach not only keeps the assembly line running smoothly but also reduces operational costs associated with emergency repairs and lost production time. As companies continue to invest in these advanced control systems, the potential for achieving maximum efficiency becomes increasingly attainable.

| Parameter | Current Value | Target Value | Improvement (%) |

|---|---|---|---|

| Throughput (units/hour) | 150 | 200 | 33.33% |

| Downtime (hours/week) | 10 | 5 | 50% |

| Energy Consumption (kWh/week) | 300 | 250 | 16.67% |

| Defect Rate (%) | 5 | 2 | 60% |

| Lead Time (days) | 7 | 4 | 42.86% |

In today's competitive manufacturing landscape, optimizing efficiency on heavy roller conveyor assembly lines is crucial. One of the key aspects of achieving maximum efficiency is the implementation of effective maintenance strategies, particularly predictive maintenance. According to a report by McKinsey & Company, predictive maintenance can reduce unplanned downtime by up to 50%, translating to significant cost savings and increased productivity. By utilizing data analytics and Internet of Things (IoT) technology, manufacturers can monitor equipment health in real-time, allowing them to anticipate failures before they occur.

A well-executed predictive maintenance program not only minimizes downtime but also enhances the overall lifespan of the machinery. The reliability of conveyor systems can be greatly improved: a study from Deloitte indicates that organizations deploying predictive maintenance strategies can realize up to a 30% reduction in maintenance costs. As heavy roller conveyor systems are integral to assembly line functionality, investing in predictive maintenance tools and techniques is essential for maximizing efficiency, ensuring smooth operations, and maintaining a competitive edge in the manufacturing sector.

Effective training and safety protocols are crucial for enhancing workforce engagement in heavy roller conveyor operations. According to industry reports, companies that invest in comprehensive training programs experience a 30% reduction in workplace accidents and improve overall productivity by 24%. This highlights the direct connection between a well-trained workforce and operational efficiency. By employing techniques such as simulation-based training and hands-on workshops, employers can empower workers to confidently handle machinery and understand safety protocols, which ultimately leads to a more engaged workforce.

Tips: Implement regular safety drills and refresher courses to keep safety top of mind. Create a culture of communication where employees feel encouraged to report unsafe practices or equipment malfunctions without fear of reprimand. Establishing clear safety guidelines and ensuring they are accessible can also enhance adherence and awareness among staff.

Moreover, providing incentives for following safety protocols can lead to higher compliance rates. For instance, a study found that companies offering rewards for accident-free months saw a 15% increase in safety compliance. Such initiatives not only foster a safety-first mindset but also contribute to overall workplace morale, making employees feel valued and engaged in their roles.