Upgrading your Conveyor Equipment can significantly enhance operational efficiency and productivity, as revealed by recent industry studies. According to a report by the Material Handling Industry of America (MHIA), over 70% of companies that enhanced their conveyor systems experienced a notable increase in throughput, leading to improved profitability and reduced operational costs. In an era where automation and logistics play a vital role in supply chain management, investing in modern and advanced Conveyor Equipment becomes essential. Furthermore, the market for conveyor systems is projected to grow at a CAGR of 4.9% through 2027, highlighting the increasing recognition of the importance of efficient material handling in various sectors. With such compelling data, it is clear that upgrading your conveyor systems is not just an option but a necessity to stay competitive in today's fast-paced industrial landscape.

Upgrading conveyor equipment can significantly influence operational costs, making it a strategic investment for many businesses. According to a report by the Material Handling Industry of America (MHIA), modern conveyor systems can enhance productivity by up to 25%, reducing the time needed for material handling. The ability to quickly and efficiently move products through various stages of the production and distribution process leads to less downtime and faster turnaround times, translating to lower operating expenses.

Moreover, energy costs are becoming increasingly critical in evaluating operational efficiency. A study conducted by the U.S. Department of Energy indicated that advanced conveyor systems equipped with energy-saving technologies can cut energy consumption by up to 30%. As businesses strive to reduce their carbon footprint while minimizing costs, the adoption of efficient conveyor solutions provides a dual advantage. Furthermore, reducing energy consumption not only enhances profitability but also aligns with sustainability goals that are becoming essential for modern enterprises.

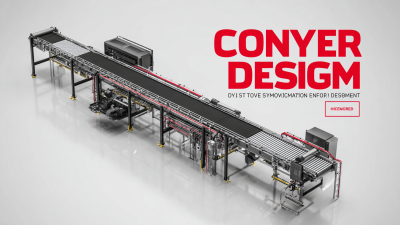

Upgrading conveyor equipment is a strategic move that can significantly enhance operational efficiency in various industries. Modern conveyor technology integrates advanced features such as smart sensors, real-time data monitoring, and automated controls. These innovations allow businesses to streamline their workflows, reduce manual handling, and minimize downtime. By implementing an upgraded conveyor system, companies can improve material handling processes, ensure more consistent product delivery, and ultimately boost productivity.

Upgrading conveyor equipment is a strategic move that can significantly enhance operational efficiency in various industries. Modern conveyor technology integrates advanced features such as smart sensors, real-time data monitoring, and automated controls. These innovations allow businesses to streamline their workflows, reduce manual handling, and minimize downtime. By implementing an upgraded conveyor system, companies can improve material handling processes, ensure more consistent product delivery, and ultimately boost productivity.

Moreover, modern conveyors are designed to be more adaptable and versatile, accommodating a wider range of products and materials. This flexibility enables businesses to swiftly respond to market demands and changes in production schedules. With energy-efficient designs, these systems not only cut energy costs but also support sustainability goals. Investing in contemporary conveyor technology not only propels efficiency forward but also positions companies to stay competitive in an ever-evolving market landscape.

Upgrading conveyor equipment not only enhances operational efficiency but also plays a crucial role in improving workplace safety standards. Modern conveyors are designed with advanced safety features that significantly reduce the risk of injuries. For instance, advanced sensors and automatic shut-off mechanisms can detect potential hazards before they escalate, allowing for immediate corrective action. This proactive approach minimizes accidents related to equipment malfunctions, protecting workers from serious injuries.

Moreover, upgraded conveyors often come with ergonomic designs that reduce physical strain on employees. Features such as adjustable heights and better alignment help minimize repetitive movements and awkward postures, which are common contributors to workplace injuries. By investing in modern conveyor systems, businesses not only ensure compliance with safety regulations but also foster a safer work environment where employees can perform their tasks confidently. This focus on safety ultimately leads to higher employee morale and productivity, creating a win-win situation for both workers and employers.

Investing in efficient conveyor systems is not just a smart business move; it also has significant environmental benefits. According to a report by the International Energy Agency, industrial processes contribute to nearly 30% of global carbon emissions, with conveyor systems accounting for a notable portion of that energy consumption. By upgrading to modern, energy-efficient conveyor equipment, companies can reduce their energy use by up to 30%, thereby lowering their carbon footprint and contributing to global sustainability efforts.

Moreover, efficient conveyor systems can optimize material flow, reducing waste and increasing productivity. The U.S. Department of Energy states that by improving operational efficiency in manufacturing, facilities can achieve energy savings of 10% to 20%. This reduction not only enhances sustainability but also translates into lower operational costs, aligning economic and environmental goals. Transitioning to eco-friendly conveyor systems positions businesses as leaders in sustainability, fostering a positive brand image while actively participating in the fight against climate change.

| Benefit | Description | Sustainability Impact |

|---|---|---|

| Energy Efficiency | Modern conveyor systems use less energy, reducing operational costs. | Lower energy consumption leads to reduced carbon footprint. |

| Waste Reduction | Efficient materials handling minimizes product damage and waste. | Decreasing waste contributes to landfill reduction. |

| Automation | Upgraded systems enable greater automation, increasing productivity. | Enhancing productivity reduces the need for additional resources. |

| Improved Safety | New systems include safety features that protect workers. | Safer working conditions promote sustainable labor practices. |

| Longer Lifespan | Upgraded materials and design increase the lifespan of equipment. | Durable systems mean less frequent replacements, reducing waste. |

| Adaptability | Modern conveyors can be easily reconfigured for different products. | Versatile systems reduce the need for multiple machines. |

| Lower Maintenance Costs | Advanced technology reduces wear and need for repairs. | Less maintenance contributes to fewer resources used over time. |

Upgrading your conveyor equipment is crucial for staying competitive in today's fast-evolving industrial landscape. As industries strive to meet higher standards of efficiency and safety, the significance of modern conveyor systems becomes increasingly evident. The agricultural sector, for instance, is seeing substantial growth driven by innovative food-grade rubber conveyor belts that enhance processing safety and efficiency. This trend reflects the broader movement within the conveyor market, projected to reach $8.8 billion by 2030, showcasing the vital role of upgraded equipment in maintaining industry standards.

Upgrading your conveyor equipment is crucial for staying competitive in today's fast-evolving industrial landscape. As industries strive to meet higher standards of efficiency and safety, the significance of modern conveyor systems becomes increasingly evident. The agricultural sector, for instance, is seeing substantial growth driven by innovative food-grade rubber conveyor belts that enhance processing safety and efficiency. This trend reflects the broader movement within the conveyor market, projected to reach $8.8 billion by 2030, showcasing the vital role of upgraded equipment in maintaining industry standards.

Tips for successful conveyor upgrades include conducting a thorough assessment of current systems to identify areas for improvement. Investing in technology that enhances automation can also yield notable efficiency gains. Moreover, soliciting feedback from end-users will provide insights that can guide the selection of new equipment, ensuring that any upgrades meet the unique needs of your operations.

Continuous investment in advanced conveyor systems not only fosters compliance with industry standards but also positions your organization at the forefront of innovation. As the bulk material handling system market continues to grow, adopting state-of-the-art conveyor technology will ultimately lead to improved productivity and reduced operational costs, securing your competitive edge in the market.