In today's fast-paced industrial landscape, the efficiency of material handling systems is paramount for businesses aiming to stay competitive. Conveyor Systems Limited plays a crucial role in streamlining operations and optimizing workflows across various sectors. According to a recent report by the Global Conveyor Systems Market, the industry is projected to reach USD 7.8 billion by 2027, growing at a CAGR of 4.5% from 2020 to 2027. This growth underscores the importance of selecting the right conveyor system tailored to specific business needs, as an efficient conveyor solution can enhance productivity, reduce operational costs, and improve safety measures. Understanding the various types of conveyor systems available, as well as their applications and benefits, is essential for businesses to make informed decisions that align with their operational goals and industry standards.

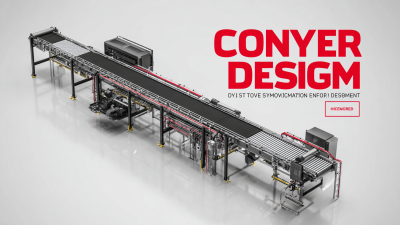

When selecting the right conveyor system for your business, it's essential to understand the various types available. The most common systems include belt conveyors, roller conveyors, and overhead conveyors.

Belt conveyors are ideal for transporting bulk materials over long distances. They are versatile and can handle a wide range of products, making them suitable for industries like manufacturing and warehousing.

Roller conveyors, on the other hand, are perfect for handling cartons and heavy loads, facilitating smooth movement without requiring a motorized drive.

Another option to consider is the overhead conveyor system, which maximizes floor space by utilizing overhead tracks. This type is particularly effective in assembly lines and distribution centers, allowing for efficient movement of goods without cluttering the ground area.

Additionally, consider whether a modular conveyor system suits your needs, offering customizable configurations that can adapt as your operations evolve. Each type has unique benefits; understanding these differences will enable you to choose a system that optimally supports your operational requirements.

When selecting the right conveyor systems for your business needs, there are several key factors to consider. First and foremost is the specific industry requirements. Different sectors, such as food and beverage, retail, and logistics, have unique demands that influence system design and function. Understanding these needs can help determine the appropriate conveyor type, whether it's a belt system for gentle handling or a roller system for heavy-duty applications.

Another crucial factor is the scalability and flexibility of the conveyor system. As market trends show a growing demand for efficiency and processing capabilities, businesses must choose systems that can adapt to fluctuating volumes and workflows. This adaptability is particularly vital in fast-paced environments like airports, where quick loading and unloading can greatly impact overall operations. By focusing on these considerations, businesses can make informed decisions that enhance productivity and support long-term growth.

When evaluating the performance and efficiency of conveyor systems for your business needs, several key factors should be considered. According to a study by the Material Handling Industry of America, efficient conveyor systems can improve operational productivity by up to 30%. This is pivotal for businesses that rely on high-volume throughput, as optimizing conveyor systems can directly impact overall operational efficiency.

Additionally, the type of conveyor system you choose should align with the specific materials being handled. For example, a report from the Conveyor Equipment Manufacturers Association indicates that belt conveyors are often more suitable for handling bulk materials, while roller conveyors excel in the transportation of packed goods. Understanding the payload capacity, speed, and reliability of the system is crucial; systems with higher reliability can reduce downtime by up to 25%, according to a survey from IndustryWeek. This data highlights the importance of selecting a conveyor system that not only meets the current needs but is also scalable for future growth.

When selecting a conveyor system for your business, assessing cost-effectiveness is crucial. It's essential to balance your budget constraints with the quality you need. Investing in a high-quality conveyor system can lead to increased efficiency and reduced maintenance costs in the long run. Therefore, conducting a thorough analysis of both initial purchase costs and ongoing operational expenses can help ensure you make a sound investment decision.

Tips: When comparing different conveyor systems, consider factors such as the material grade, operational speed, and energy consumption. These elements can significantly influence overall costs. Additionally, seek out suppliers who offer warranties and robust customer support. This can not only save you money on repairs but also ensure you have assistance when you need it.

Another important aspect is to evaluate the scalability of the conveyor system. As your business grows, your conveyor needs may change. Opting for a system that can be easily modified or expanded can safeguard your investment for the future, ensuring that you won’t have to drastically increase your budget as your operational requirements evolve. It’s vital to choose a system that provides flexibility along with quality to keep your business running smoothly.

When selecting a conveyor system, it's essential to prioritize customization and scalability to meet the dynamic needs of your business. Each industry comes with its unique set of requirements, and a one-size-fits-all solution often falls short. A customizable conveyor system allows you to tailor various components—such as length, width, material, and technology—to align perfectly with your existing workflow and product types. This adaptability not only enhances operational efficiency but also facilitates seamless integration into your production line.

As your business evolves, so will your conveyor needs. Scalability is a key feature to consider; an ideal system should be designed to grow alongside your operations. Whether you're expanding your product line, increasing production volume, or entering new markets, a scalable conveyor solution enables you to make necessary adjustments without significant additional investment. By choosing a conveyor system that offers both customization and scalability, you ensure that your operations remain efficient and competitive long into the future, accommodating changes in demand and business direction with ease.