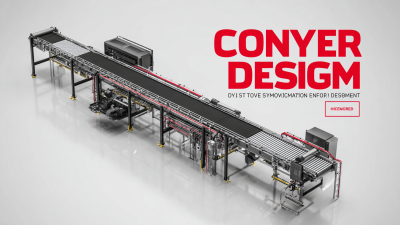

In the evolving landscape of industrial manufacturing, the optimization of production processes has become paramount for businesses aiming to stay competitive. One innovative solution that has garnered attention is the implementation of the Heavy Roller Conveyor Assembly Line. This advanced system not only enhances operational efficiency but also significantly reduces labor costs and minimizes product damage during handling. As industries look toward the future, adopting technologies like the Heavy Roller Conveyor Assembly Line becomes crucial for streamlining workflows and achieving higher throughput. In this blog, we will explore various strategies and innovations that can further enhance the efficiency of heavy roller conveyor systems, ensuring that manufacturers can meet the increasing demands of the market while maintaining quality and safety. By embracing these solutions, businesses can pave the way for a more productive and sustainable future in manufacturing.

Implementing heavy roller conveyor systems in assembly lines has been shown to significantly enhance operational efficiency, a key consideration for manufacturers aiming to compete in today's fast-paced market. According to a report by the Material Handling Industry of America (MHIA), companies that integrate advanced conveyor systems can experience productivity increases of up to 30%. This is largely due to the streamlined movement of heavy materials, reducing the need for manual handling and minimizing downtime during production processes.

In addition to boosting productivity, heavy roller conveyor systems provide substantial ergonomic benefits. Research conducted by the National Institute for Occupational Safety and Health (NIOSH) indicates that automated material handling solutions can reduce workplace injuries by 60%. These systems are designed to handle various weights and sizes of products, which alleviates stress on workers and lowers the risk of strains and injuries. By promoting a safer workplace, manufacturers not only enhance employee satisfaction but also reduce costs related to worker compensation and absenteeism. The integration of heavy roller conveyor systems thus presents a multifaceted advantage, driving efficiency and enhancing workplace safety simultaneously.

| Benefit | Description | Impact Level |

|---|---|---|

| Increased Throughput | Heavy roller conveyors facilitate the movement of heavy loads, reducing bottlenecks. | High |

| Improved Safety | Minimized manual handling reduces the risk of workplace injuries. | Medium |

| Cost Efficiency | Automation reduces labor costs over time and enhances ROI. | High |

| Flexibility | Can be easily reconfigured to accommodate different workflows. | Medium |

| Enhanced Product Handling | Heavy roller design protects products during transport. | High |

| Reduced Downtime | Long-lasting materials lower maintenance frequency. | Medium |

The efficiency of heavy roller conveyor assembly lines is increasingly being enhanced through the integration of advanced technologies. As highlighted in recent market insights, the conveyor belt market is set to expand from 5.89 billion USD in 2024 to 8.12 billion USD by 2033, reflecting a compound annual growth rate (CAGR) of 4.1%. This growth is a testament to the innovations in automation and Industry 4.0 principles that are reshaping the conveyor systems landscape.

To maximize efficiency on heavy roller conveyor assembly lines, companies should consider leveraging automation technologies. Implementing automated conveyor systems can lead to a projected market growth reaching 3.11 billion USD by 2032, with an accompanying CAGR of 3.82%. Furthermore, adopting tools like advanced PLC-based monitoring systems can enhance the reliability of operations, with a focus on maintaining optimal surface conditions for conveyor belts, critical in harsh environments.

Tips:

Heavy roller conveyor assembly lines play a crucial role in enhancing operational efficiency in various industries. To maximize their performance, it's essential to focus on five key factors: proper design, routine maintenance, appropriate speed settings, optimal load distribution, and employee training. Each of these factors can significantly impact the overall effectiveness of the conveyor system.

When designing a heavy roller conveyor, consider the specific requirements of your production line. The layout should facilitate the smooth transfer of materials while minimizing bottlenecks. Additionally, performing regular maintenance, such as lubrication and alignment checks, can prevent unexpected downtime and extend the life of the equipment.

Another critical aspect is speed settings. Adjusting conveyor speeds to match production demands can help optimize throughput. Ensure that load distribution is balanced across the rollers to avoid wear and tear, which might lead to inefficiencies. Lastly, investing in employee training will empower your team to operate the assembly line effectively, enabling them to troubleshoot minor issues before they escalate.

By concentrating on these five factors, businesses can enhance the efficiency and reliability of their heavy roller conveyor assembly lines, improving overall productivity and reducing operational costs.

To maximize the efficiency of heavy roller conveyor assembly lines, regular maintenance is essential. According to a report by the Conveyor Equipment Manufacturers Association (CEMA), routine maintenance can increase equipment lifespan by 30% and reduce operational costs by up to 15%. This highlights the significance of scheduled inspections and timely repairs to prevent costly breakdowns and production delays.

One crucial aspect of maintenance involves ensuring proper lubrication of all moving parts. A study from the National Automatic Merchandising Association (NAMA) revealed that inadequate lubrication can lead to a 50% increase in wear and tear on conveyor belts. By implementing a consistent lubrication schedule and using high-quality lubricants, manufacturers can significantly enhance the performance and reliability of their conveyor systems.

Additionally, taking the time to clean the conveyor regularly is vital. The OSHA reports that 20% of workplace accidents are linked to poor housekeeping practices, including the buildup of debris on conveyor lines. By dedicating resources to keep the assembly line clean and clear, companies not only ensure safer working conditions but also facilitate smoother operations, ultimately leading to increased productivity.

In the world of manufacturing, conveyor assembly lines are essential for maintaining efficiency and productivity. However, common challenges such as bottlenecks, equipment malfunctions, and workforce management can hinder optimal performance. Innovative solutions are crucial for addressing these issues, ensuring that heavy roller conveyor systems operate smoothly and effectively.

One approach to overcoming these challenges is the integration of advanced automation technologies. By implementing smart sensors and real-time monitoring systems, manufacturers can gain valuable insights into the performance of their conveyor lines. This data facilitates proactive maintenance, minimizing unexpected downtimes and enhancing overall efficiency. Additionally, employing modular conveyor designs allows for flexibility and easier scalability, adapting to changing production demands without significant overhauls.

Moreover, fostering a culture of continuous improvement among employees can significantly impact assembly line operations. Training programs focused on best practices in process management and equipment handling further empower workers to identify and solve problems quickly. This collaborative environment not only boosts morale but also leads to innovative suggestions for streamlining operations, resulting in a more efficient and resilient conveyor assembly line.