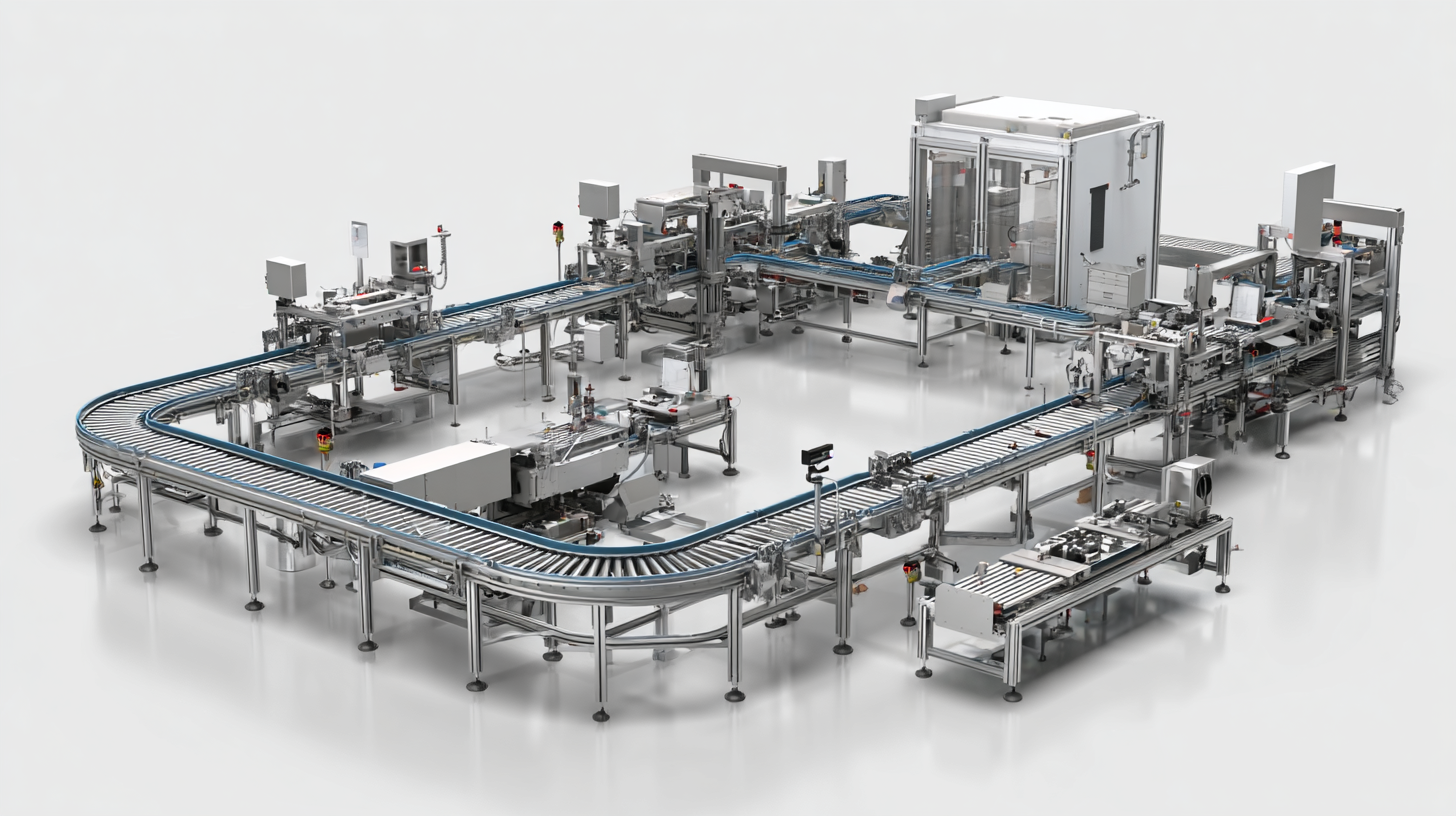

In today's fast-paced manufacturing environment, the efficiency of Assembly Conveyor Systems plays a critical role in operational success. According to a report by Research and Markets, the global conveyor systems market is projected to reach $8.5 billion by 2026, emphasizing the increasing reliance on advanced conveyor solutions across industries. Optimizing these systems is essential not only for enhancing throughput but also for reducing operational costs. Effective design and strategic implementation of conveyor systems can lead to improvements in productivity by up to 30%, as highlighted by a recent study from the Material Handling Industry of America (MHIA). As manufacturers seek to streamline processes and minimize downtime, understanding how to fine-tune assembly conveyor systems becomes paramount for achieving maximum efficiency and maintaining a competitive edge in the marketplace.

In today's rapidly evolving manufacturing landscape, understanding the various types of assembly conveyor systems and their applications is crucial for optimizing efficiency. Conveyor systems, which include belt conveyors, roller conveyors, and automated guided vehicles (AGVs), serve as the backbone of production lines across diverse industries. With a projected global energy-efficient motor market size increasing from $51.65 billion in 2024 to $84.72 billion by 2030, integrating energy-efficient technologies into these systems is paramount. Utilizing advanced motors can significantly enhance the performance of conveyor systems, resulting in reduced energy consumption and lower operational costs.

Moreover, the rise of Industry 4.0 is revolutionizing conveyor technology by incorporating automation and data exchange into manufacturing processes. As industries modernize, automated monitoring and control systems for conveyor belts have become increasingly essential. Reports indicate that the semiconductor industry's automated material handling systems (AMHS) market is expected to grow from USD 3.14 billion in 2024 to around USD 6.20 billion by 2034. This reflects a broader trend toward leveraging technology and innovative solutions to meet the growing demands for efficiency and precision in assembly processes. The synergy of these advancements in conveyor systems not only enhances operational efficiency but also propels companies towards future-ready manufacturing capabilities.

When optimizing assembly conveyor systems, it is crucial to focus on key metrics that measure their efficiency. One of the primary metrics is the energy consumption, especially for inclined conveyors where grade resistance significantly impacts performance. By analyzing the energy requirements, companies can identify areas for improvement, reducing operational costs while enhancing productivity.

Another essential metric is the wear rate of conveyor belts. This is particularly vital in the bulk materials handling industry, where understanding the deterioration of belts can lead to better maintenance strategies and extended equipment lifespan. Implementing predictive models allows businesses to anticipate failures instead of reacting to them, ensuring smoother operations and less downtime.

Furthermore, advancements in technology, such as radar-based monitoring systems, have revolutionized how conveyor system efficiency can be measured and improved. These systems provide real-time data on material flow, helping operators make informed decisions to optimize performance. By closely monitoring these key metrics, companies can achieve maximum efficiency in their conveyor operations.

In today's manufacturing landscape, optimizing assembly conveyor systems is crucial for maximizing efficiency and productivity. Innovative technologies play a pivotal role in enhancing conveyor performance. For instance, the integration of IoT (Internet of Things) sensors allows for real-time monitoring of conveyor systems. According to a report by MarketsandMarkets, the IoT in manufacturing market is projected to reach $450 billion by 2025, reflecting a significant shift towards smart manufacturing processes. These sensors enable predictive maintenance, reducing downtime by up to 30%, which can significantly impact overall operational efficiency.

Moreover, advancements in conveyor belt materials and design, such as modular belts and antimicrobial surfaces, have been shown to improve both durability and hygiene in assembly lines. Research from the Conveyor Equipment Manufacturers Association (CEMA) indicates that using high-performance materials can increase conveyor lifespan by 50%, ultimately lowering replacement costs. Additionally, incorporating automation technologies like robotic arms and AI-driven sorting systems can streamline operations further, leading to a potential increase in throughput by over 40%. As these innovative solutions continue to evolve, manufacturers will find themselves better equipped to meet the demands of a rapidly changing market.

This chart illustrates the efficiency improvements observed in assembly conveyor systems following technological upgrades, showcasing a significant increase from 70% to 90% efficiency.

When striving for maximum efficiency in assembly conveyor systems, several common challenges often arise. One prevalent issue is the bottleneck created by uneven load distribution. This can lead to operational delays and increased wear on certain components. To address this, implementing load balancing techniques can streamline the flow of materials. Utilizing sensors and real-time data analytics allows operators to monitor load distribution continuously and make adjustments as necessary, ensuring an even flow across the conveyor.

Another challenge is the frequent need for maintenance due to wear and tear on conveyor belts and components. Regular maintenance schedules are essential, but integrating predictive maintenance technology can significantly enhance reliability. By employing IoT sensors that monitor conveyor performance and predict potential failures, systems can be serviced proactively. This not only reduces downtime but also contributes to a more efficient assembly line, allowing for consistent production rates and lower operational costs. By tackling these common issues with effective solutions, companies can optimize their conveyor systems for improved efficiency and productivity.

Maintaining assembly conveyor systems is crucial for optimizing operational efficiency and reducing downtime. According to a report by the Conveyor Equipment Manufacturers Association, proper maintenance can extend the lifespan of conveyor systems by up to 50%, significantly reducing replacement costs. Regular inspections and timely repairs not only prevent unexpected failures but also enhance overall productivity. For instance, a facility that implements a structured maintenance program can improve its output by 20% by minimizing unplanned disruptions.

Best practices for maintaining conveyor systems include conducting routine cleaning, lubrication, and alignment checks. The International Journal of Industrial Engineering highlights that organizations employing predictive maintenance strategies experience a 30% reduction in maintenance costs. By utilizing advanced sensors and IoT technology, businesses can monitor the health of their conveyor systems in real-time, allowing for timely intervention before minor issues escalate. Investing in a robust maintenance plan not only ensures long-lasting efficiency but also empowers companies to meet fluctuating production demands effectively.