The rapid evolution of warehouse operations is significantly influenced by advancements in technology, particularly through the implementation of Industrial Conveyor Systems. According to a 2023 report by Logistics Management, the global market for conveyor systems is expected to reach $9.2 billion by 2026, driven by increasing demand for automation and efficiency in logistics and warehousing.

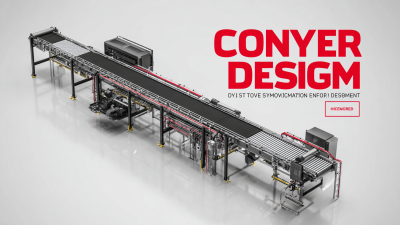

Industrial conveyor systems are poised to revolutionize warehouse productivity by streamlining supply chain operations. With the integration of advanced robotics and sensor technologies, warehouses are witnessing extraordinary improvements in efficiency, accuracy, and cost-effectiveness. As companies adopt automated solutions, the reliance on manual labor diminishes, enabling businesses to meet rising demands swiftly and effectively.

Industrial conveyor systems are poised to revolutionize warehouse productivity by streamlining supply chain operations. With the integration of advanced robotics and sensor technologies, warehouses are witnessing extraordinary improvements in efficiency, accuracy, and cost-effectiveness. As companies adopt automated solutions, the reliance on manual labor diminishes, enabling businesses to meet rising demands swiftly and effectively.

Tips for boosting efficiency: Consider implementing AI-powered inventory management systems that optimize stock levels and minimize errors. Additionally, leveraging autonomous mobile robots can significantly cut down on manual handling times and improve throughput in your warehouse.

Moreover, the current trend of incorporating emerging technologies like IoT into warehouse automation is reshaping how logistics processes are managed. By integrating these advancements, companies can achieve real-time tracking and enhanced decision-making capabilities, ensuring a more responsive and resilient supply chain. Embracing these innovations is essential for organizations looking to thrive in an increasingly competitive marketplace.

The integration of advanced conveyor technologies in warehouse operations is setting a new standard for real-time data tracking and performance enhancement. By utilizing smart conveyor systems equipped with sensors and IoT connectivity, businesses can monitor the flow of goods and gather invaluable data on operational efficiency. This technology allows for continuous assessment of the conveyor’s performance, enabling managers to identify bottlenecks and streamline their processes effectively.

Furthermore, real-time data insights empower warehouse personnel to make informed decisions quickly. Automated alerts can signal when maintenance is needed or when specific tasks are falling behind schedule. This proactive approach not only minimizes downtime but also enhances overall productivity. As companies increasingly rely on swift and reliable logistics, the adoption of these sophisticated conveyor systems proves critical in maintaining competitive advantage in a rapidly evolving industry.

In the competitive landscape of warehousing, implementing advanced industrial conveyor systems can significantly reduce operational expenses. According to a report by the Material Handling Industry of America (MHIA), automated conveyor systems can lower labor costs by 20-25%, reflecting a crucial step towards optimizing warehouse efficiency. These systems streamline the movement of goods, reducing the need for manual handling and minimizing the likelihood of errors, which can be costly.

Moreover, integrating conveyor systems leads to better space utilization. A study by the Warehousing Education and Research Council found that warehouses utilizing integrated conveyor systems could improve their storage capacity by 30%. This increased efficiency not only enhances productivity but also allows businesses to handle more inventory without needing to expand their physical footprint.

Tip 1: Regularly assess your conveyor system to identify areas for improvement, such as adjusting speeds or updating technology, to ensure it meets your warehouse demands.

Tip 2: Invest in employee training to maximize the benefits of your conveyor system, improving safety and system efficiency across your operations.

The rapid development of Industry 4.0 and smart factories is undeniably reshaping logistics, driving the demand for advanced automation in the warehouse sector. Artificial Intelligence (AI) and automation technologies are now at the forefront of revolutionizing conveyor systems, enhancing the efficiency of material handling. As logistics becomes increasingly complex, integrating AI into conveyor systems facilitates real-time data analytics and improves operational agility.

**Tips for Implementation:** Consider starting with a pilot project that incorporates AI-driven conveyor systems. This allows businesses to assess the technology's impact on efficiency before a full-scale rollout. Additionally, investing in staff training will ensure that employees can effectively use the new systems and understand the data insights generated.

As we look towards 2024-2032, the retail logistics market is projected to grow substantially, with a compound annual growth rate of around 10%. This growth is significantly influenced by the surge of direct-to-consumer companies that leverage advanced logistics strategies powered by AI. Embracing these technologies is no longer optional but essential for firms aiming to remain competitive in an evolving market landscape.

**Tips for Growth:** Stay updated on the latest trends in AI and automation within logistics. Collaboration with technology providers can enhance your operational capacity and ensure you are at the forefront of industry innovations.

| Dimension | Current Value | Projected Value (2025) | Growth Rate (%) |

|---|---|---|---|

| Automated Conveyor Length (km) | 12 | 20 | 66.7 |

| Number of Automated Pick Stations | 30 | 75 | 150 |

| Parcel Sortation Speed (items/hour) | 1500 | 3000 | 100 |

| Reduction in Labor Costs (%) | 30 | 50 | 66.7 |

| System Downtime (%) | 15 | 5 | -66.7 |

In today's fast-paced logistics environment, advanced industrial conveyor systems play a pivotal role in enhancing warehouse productivity. Case studies have shown that organizations implementing state-of-the-art conveyor solutions can achieve remarkable efficiency gains. For instance, a leading e-commerce company reported a 30% decrease in order processing time after integrating automated conveyor systems tailored to their unique workflow requirements. These systems not only streamline the movement of goods but also significantly reduce labor costs by minimizing manual handling.

Tips for Implementation: Utilize a Modular Approach When considering the adoption of advanced conveyor solutions, think modular. This allows for flexibility in scaling operations as demand fluctuates, making it easier to adapt to changing business needs without a complete overhaul of the existing system.

Tips for Continuous Improvement: Regularly Analyze Data Integrate data analytics into your conveyor systems to monitor performance in real-time. By regularly analyzing this data, warehouses can identify bottlenecks and inefficiencies, enabling continuous improvement and further enhancements in productivity.

By leveraging these insights and focusing on innovative conveyor technologies, warehouses can position themselves to meet the increasing demands of modern logistics.