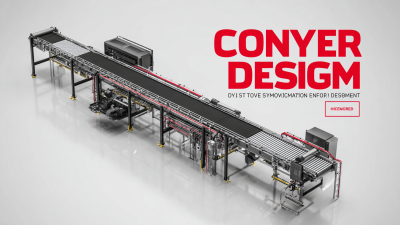

In today's fast-paced industrial landscape, an effective Conveyor System Design is crucial for enhancing productivity and optimizing workflow. Whether you're involved in manufacturing, warehousing, or logistics, the right conveyor system can significantly impact your operations by streamlining processes, reducing manual labor, and minimizing downtime. This comprehensive guide aims to equip you with essential tips for designing a conveyor system that meets your unique operational needs.

From selecting the appropriate components and understanding material flow to considering safety regulations and cost-efficiency, this blog will delve into the key aspects that contribute to a well-functioning conveyor system. By following the insights provided here, you can ensure that your conveyor system not only performs efficiently but also adapts to future challenges and technological advancements.

When selecting the right conveyor type for your needs, it’s crucial to consider the specific requirements of your operation. One key consideration is the material being transported. Different materials have varying characteristics, such as weight, fragility, and bulkiness, which can significantly influence the type of conveyor system that will work best. For instance, if you are moving heavy materials like metals, a robust roller conveyor may be a preferable choice, while fragile items might require a gentler belt conveyor.

Another essential tip is to evaluate the layout of your facility. The design of the conveyor system must adapt to both the available space and the workflow. Consider the height, length, and capacity needed for your operations. Implementing a modular conveyor system can provide flexibility, allowing you to easily adjust the configuration as your needs change. Additionally, think about the system's integration with existing machinery; seamless connectivity is vital for maintaining efficiency.

Lastly, don’t overlook maintenance requirements. Choose a conveyor system that offers easy access for repairs and routine checks. Systems that are easier to maintain can save you both time and money in the long run, ensuring your operation runs smoothly. By focusing on these key considerations, you can select a conveyor system that will enhance productivity and streamline your processes.

| Conveyor Type | Application | Load Capacity (lbs) | Speed (ft/min) | Cost ($/ft) |

|---|---|---|---|---|

| Belt Conveyor | Material Handling | 2000 | 100 | 20 |

| Roller Conveyor | Package Handling | 1500 | 50 | 15 |

| Chain Conveyor | Heavy-Duty Transport | 3000 | 30 | 25 |

| Bucket Conveyor | Bulk Material Handling | 1000 | 40 | 30 |

| Screw Conveyor | Powder and Granule Transport | 1200 | 20 | 35 |

When designing an efficient conveyor system layout, it is crucial to focus on several top design principles that can optimize the flow of materials. According to a report by the Material Handling Industry of America (MHIA), properly designed conveyor systems can improve productivity by 30% or more. This efficiency stems from effective space utilization and the reduction of manual handling, which minimizes the chances of errors and injuries.

One essential principle is the importance of understanding the product flow and load characteristics. A study conducted by the Association for Packaging and Processing Technologies indicated that up to 70% of conveyor-related inefficiencies result from inadequate layout planning. It is crucial to strategically design the pathway of the conveyor to accommodate changes in load volume and to ensure that the system can handle the specific dimensions and weights of various products. Additionally, employing flexible conveyor designs allows for future modifications and scalability, giving businesses the agility needed to adapt to market demands.

Another key consideration is the alignment of conveyor systems with overall operational goals. Integrating data analytics in the design process can provide insights into workflow bottlenecks and help in creating a more streamlined system. A survey by Logistics Management revealed that 52% of organizations are utilizing automation and technology in their material handling processes, highlighting the trend toward data-driven decisions in Conveyor system design. By focusing on these design principles, companies can cultivate an efficient and effective conveyor system that meets their evolving operational needs.

When designing a conveyor system, two critical factors come into play: conveyor speed and load capacity. Evaluating these metrics is essential for ensuring optimal performance in material handling processes. According to a recent report by the Material Handling Industry of America (MHIA), the overall efficiency of a conveyor system can drastically improve by accurately matching the conveyor speed with the flow rates of the materials being transported. Typically, conveyor speeds can range from 30 to 300 feet per minute, and setting this pace correctly can minimize downtime and enhance throughput.

Load capacity directly impacts the longevity and reliability of a conveyor system. For example, a study by the Conveyor Equipment Manufacturers Association (CEMA) indicates that improper load distribution can lead to significant wear on key components, shortening their lifespan. It’s vital to calculate the total weight of the items being transported and choose conveyor components that can accommodate 25% more than the expected load. This precaution not only improves the durability of the system but also caters to future scalability, allowing businesses to adapt to changing demands without unnecessary investments in new equipment. Thus, balancing speed and load capacity is essential for a resilient and effective conveyor system design.

Maintaining an efficient conveyor system is crucial for enhancing productivity and minimizing operational downtime. According to a recent industry report by the Conveyor Equipment Manufacturers Association, proper maintenance can reduce the risk of unexpected breakdowns by up to 70%. This makes it essential for operators to adopt best practices for regular inspections and timely repairs. Regularly checking for wear and tear, lubrication of moving parts, and ensuring the alignment of the conveyor system are simple yet effective strategies to extend the life of your equipment.

One practical tip is to implement a routine maintenance schedule that includes daily checks and weekly comprehensive inspections. This proactive approach can help identify potential issues before they escalate, saving both time and money in the long run. Additionally, utilizing technology such as vibration analysis sensors can help detect anomalies in system performance, allowing for predictive maintenance rather than reactive repairs.

Another crucial aspect of conveyor system maintenance is employee training. Ensuring that all operators are knowledgeable about the machinery they work with can significantly enhance troubleshooting efficiency. Data from the National Institute for Occupational Safety and Health suggests that companies investing in regular training see a 30% reduction in workplace accidents related to equipment handling. By fostering a well-informed workforce, businesses can enhance the operational reliability of their conveyor systems.

Innovative technologies play a pivotal role in enhancing the efficiency and performance of conveyor systems across various industries. According to the latest report from MarketsandMarkets, the conveyor systems market is expected to grow from $7.9 billion in 2022 to $10.7 billion by 2027, reflecting a CAGR of 6.6%. This growth is largely driven by advancements in automation and smart technologies that streamline operations, reduce downtime, and optimize material flow.

One of the key innovations making waves in conveyor technology is the integration of IoT (Internet of Things) devices. These systems allow for real-time monitoring and predictive maintenance, leading to a reduction in unexpected failures by up to 30%, as reported by Deloitte. Additionally, AI algorithms can now analyze conveyor performance data, enabling businesses to make informed decisions that enhance throughput and reduce energy consumption. For instance, automated guided vehicles (AGVs), when combined with conveyor systems, can effectively enhance logistics operations by improving loading speeds and minimizing manual handling, resulting in up to 50% increase in efficiency in warehouse environments.